I.What is PPS?

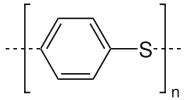

As a new type of engineering plastic for injection molding, PPS (polyphenylene sulfide) is a white, highly crystalline polymer with a density of 1.34. PPS is a polymer with a thiophenyl group on the main chain of the molecule. Due to its structure that the benzene ring and the sulfur are alternately connected, the molecular chain features a great rigidity and regularity. As a result, PPS is a crystalline polymer with multiple excellent properties, such as heat resistance, rigidity, flame retardancy and electrical insulation.

II. Selection of Injection Molding Machine

1. Molding Machine

1. Clamping force

The fluidity of PPS is similar to that of ABS and POM. When calculating the clamping force, the factor of fluidity must be taken into consideration. During material selection, the fluidity characteristic, K value should be the same as that of ABS and POM.

2. Injection Volume

Select the appropriate injection volume according to the weight of the product. It is inappropriate to use an injection molding machine with an injection volume exceeding the excessive amount, so as to prevent the material from staying in the barrel for too long and causing oxidative crosslinking reaction or even curing, resulting in product discoloration or affecting product performance or quality.

3. Screw & Barrel

According to its characteristics, PPS is not corrosive, so for common PPS materials, conventional screws can be adopted. In most cases, PPS is added with glass fiber to reinforce its various properties, but these materials cause great wear to the barrel and the screw, so wear-resistant barrel and screw should be selected, e.g., hard chrome plated screw or bimetallic screw and barrel.

4. Nozzle

An open nozzle with an inner diameter of φ3-6mm should be selected. It is better if the heater of the nozzle is separately controlled, which facilitates the molding process.

III. Injection Molding conditions of PPS

1. Material Drying

Since PPS has a low hygroscopicity, drying is not necessary before injection molding. However, if the raw material is placed in an open environment with high temperature and high humidity for too long, then it needs to be dried under the 150-160°C temperature conditions for 2-3 hours.

2. Molding Temperature

The molding temperature of PPS is relatively higher, with the barrel temperature ranging between 280 and 360℃. On the premise of ensuring smooth mold filling and product quality, the barrel temperature should be kept as low as possible, so as not to cause oxidative crosslinking of the material or even curing in the barrel. The temperature of the nozzle should be controlled separately to maintain the satisfactory fluidity of the material without clogging or dripping.

3. Injection Pressure

The injection pressure is between 50-200MPa. In order to ensure the mechanical properties and dimensional accuracy of the product, it is better to use a higher injection force, especially for complex shaped and thin-walled products.

4. Injection Speed

When the injection speed is fast, the surface finish and strength of the product will be high, but excessive injection speed will cause the product to warp, burn, etc. Usually, a medium injection speed is preferred.

5. Screw Speed

The screw speed can be kept between 50 and 200rpm. The high-speed injection molding can adopt a higher screw speed. At this point of time, the temperature of the material rises due to the high shear rate, so the barrel temperature must be lowered.

6. Holding Pressure

To prevent the generation of internal stress, the holding pressure should be as low as possible to compensate for the shrinkage, as long as the product does not appear to be depressed.

7. Backpressure

A certain level of backpressure is conducive to mold venting and material mixing, so as to get a more stable product. The backpressure usually ranges between 0.5 and 1.5MPa. For the poorly dried material, the backpressure can be higher.

8. Mold Temperature

PPS is a crystalline polymer, so the mold temperature has a direct influence on the crystallinity of the product, resulting in varied performances and dimensional accuracy. The difference in mold temperature causes a large difference in crystallization, e.g., 8% at 94°C and 48% at 150°C. The high the mold temperature, the higher crystallinity and the better the mechanical properties of the final product.

9. Molding Cycle

Since PPS is a crystalline polymer, to obtain satisfactory mechanical properties, it is necessary to adopt a higher mold temperature and a longer cooling time. For complex and thick-walled products, it is also necessary to appropriately extend the pressure holding time.

10. Product Post-treatment

In order to improve the performance, eliminate the internal stress, as well as maintain the performance and the dimensional stability of the product, annealing treatment with an oven can be performed, usually at 200-240℃ for 2-4 hours.

11. Use of Recycled Material

The recycled material can be used together with the new material, of which the proportion depends on the performance requirements of the product, but usually no more than 30%, so as not to cause a significant decrease in product performance and quality.

12. Machine Shutdown

Due to its strong adhesion to metal, after injection molding, the PPS material sticking on the barrel and the screw must be cleaned before machine shutdown, otherwise the material will firmly stick on the screw after cooling, thus affecting the next molding cycle or the production with other materials. Usually, high-density polyethylene (HDPE) is used to clean the barrel; if the production process needs to be interrupted for a period of time, the material in the barrel must be completely discharged, while the barrel temperature should be lowered to 270℃ or below, because the melt will decompose and emit toxic gases when heated under high temperature conditions for too long, so good ventilation must be maintained at the production site.