Common Surface Finishes for Plastic Injection Molds include Polishing ,Thin Fire Texture ,Texture,Plating,sand blasting

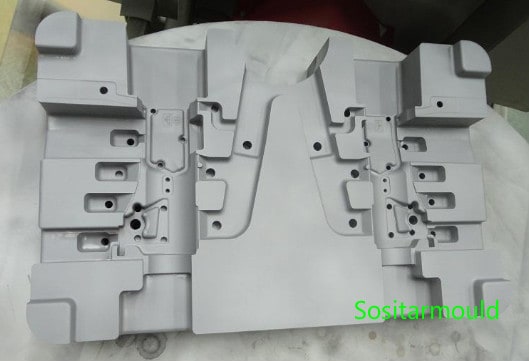

1.Polishing

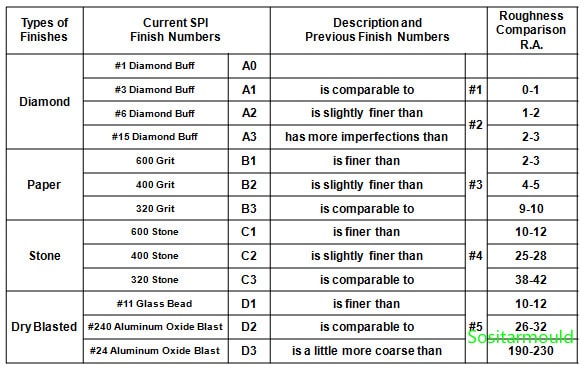

The method to remove the convex part and machining marks on the steel surface, to obtain a smooth polishing effect, mainly realized by cutting. Whetstone, wool wheel and sandpaper, etc., are usually used mainly by manual operation.there are a popular standard for classify the polish levers:SPI (Society of the Plastics Industry)

Diamond Mold Polishing & Finishing Specifications

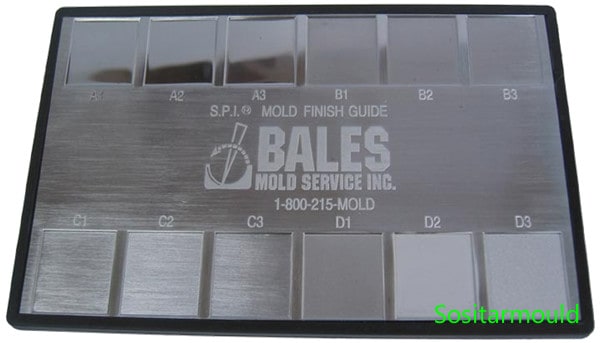

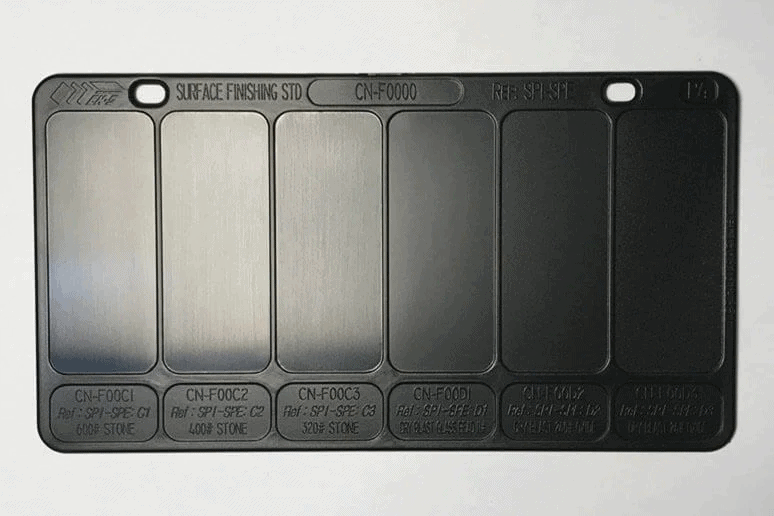

SPI finish plaque

SPI Finish A1, SPI Finish A2, SPI Finish A3, SPI Finish B1, SPI Finish B2, SPI Finish B3

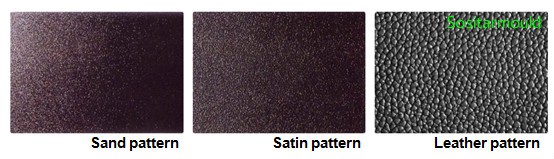

2.Texture

Immerse the spray-printed and film-attached mold in the adjusted chemical liquid to corrode the bright part. After the corrosion, the mold surface is blackened and etched to different texture pattern

Mold Tech is a very popular texture standard in mold industrial, Below is description about Mold Tech texture depth and corresponding draft angle needed on mold surface.

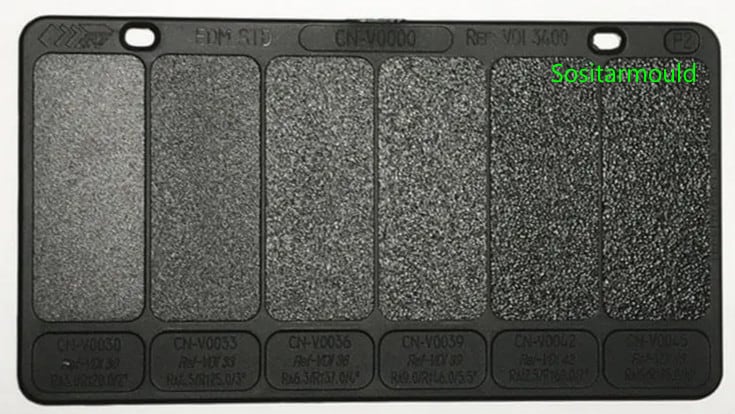

3.Thin Fire Texture

After EDM processing, the texture is left on the plastic injection mold. Usually, electrode thin fire texturing is not specially performed due to the high cost.

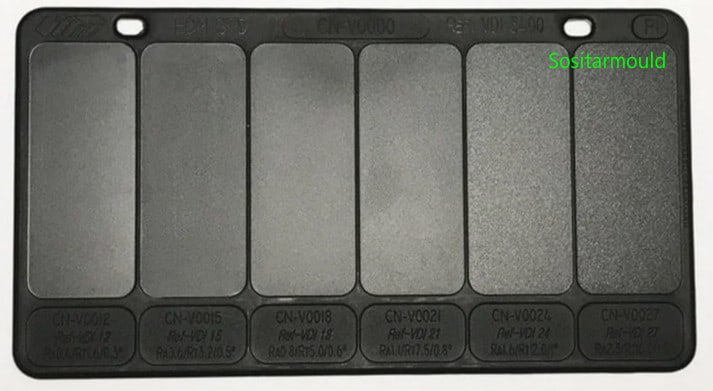

CHARMILL VDI3400 Specification

| No. | Texture depth(mm) | No. | Texture depth(mm) | |

| 0 | 0.00040 | 21 | 0.00448 | |

| 1 | 0.00044 | 22 | 0.00504 | |

| 2 | 0.00048 | 23 | 0.00560 | |

| 3 | 0.00056 | 24 | 0.00648 | |

| 4 | 0.00064 | 25 | 0.00720 | |

| 5 | 0.00072 | 26 | 0.00800 | |

| 6 | 0.00080 | 27 | 0.00880 | |

| 7 | 0.00088 | 28 | 0.01000 | |

| 8 | 0.00100 | 29 | 0.01120 | |

| 9 | 0.00112 | 30 | 0.01280 | |

| 10 | 0.00128 | 31 | 0.01400 | |

| 11 | 0.00140 | 32 | 0.01600 | |

| 12 | 0.00160 | 33 | 0.01800 | |

| 13 | 0.00180 | 34 | 0.02000 | |

| 14 | 0.00200 | 35 | 0.02240 | |

| 15 | 0.00224 | 36 | 0.02520 | |

| 16 | 0.00252 | 37 | 0.02800 | |

| 17 | 0.00280 | 38 | 0.03200 | |

| 18 | 0.00320 | 39 | 0.03600 | |

| 19 | 0.00360 | 40 | 0.04000 | |

| 20 | 0.00400 | 41 | 0.04480 |

4. Plating

The process that uses electrolysis to deposit metals or alloys on the surface of the workpiece to form a uniform, dense and well-bonded metal layer, i.e., electroplating.

5. Sand Blasting

Sand blasting is a process of workpiece surface treatment, which uses compressed air as the power to form high-speed injection that delivers the spray material to the surface of the workpiece to be processed, so that the surface appearance or shape changes.