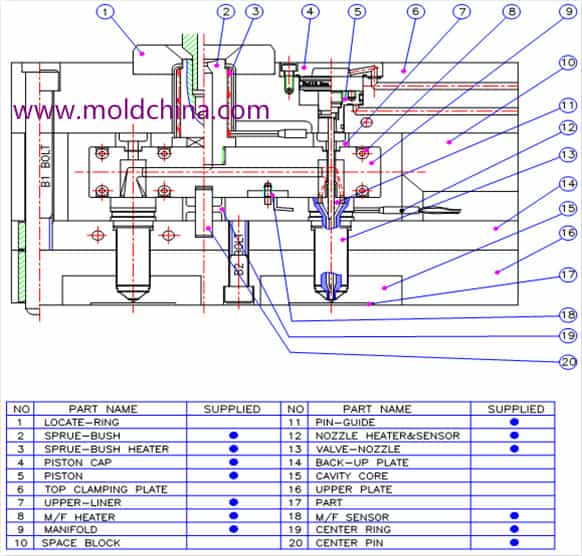

A hot runner system mold is equipped with heating devices on the sprue and runners, on basis of a traditional two-plate or three-plate mold, so that the plastic in the runner is always in a molten state, so as to eliminate or reduce cold slug for the runners.

Pros of Hot Runner Systems

1.Reduce the molding cycle. Reduce injection time and cooling time, improve mold productivity

2. Reduce cold slugs in the runner, and lower injection cost.

3. Reduced energy loss and venting burden on the melt.

4. Improve molding quality.

5. Easy for realization of automated production.

6. Simplified mold operation and increased service life

Cons of Hot Runner Systems

1. Increased overall mold closing height;

2. Thermal expansion;

3. Increased mold making costs;

4. It takes time to change the color or resin;

6. The plastic in the hot runner is easy to deteriorate;

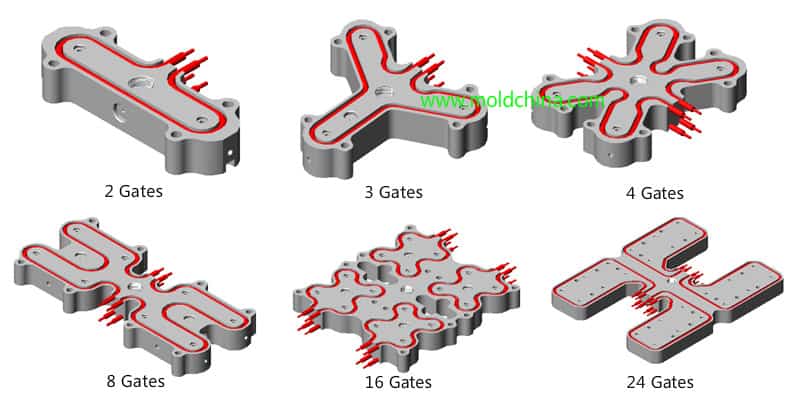

7. Restricted cavities layout;

8. High technical requirements – including such issues as wiredrawing when the runner is cut off, tips block, and balance between heating elements.

9. High plastic material requirements – plastics applicale for hot runners are: PE, ABS, POM, PC, HIPS, PS and PP.

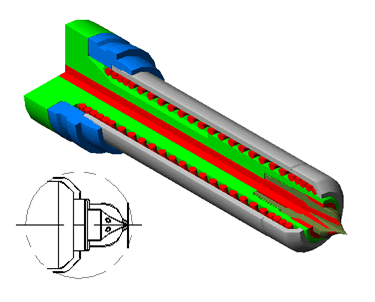

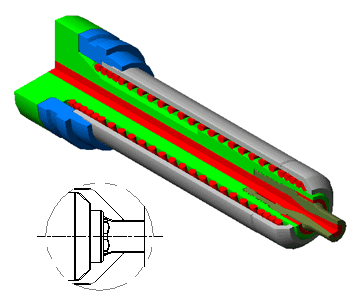

The types of hot runner system

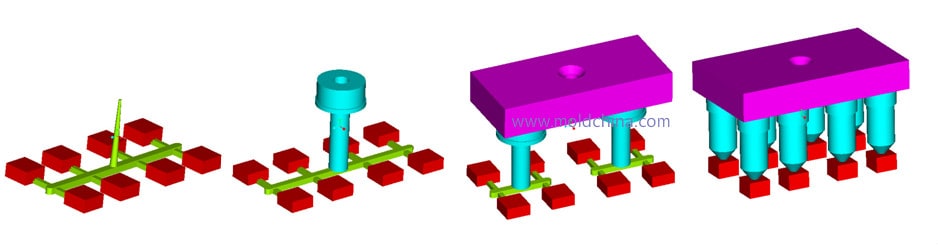

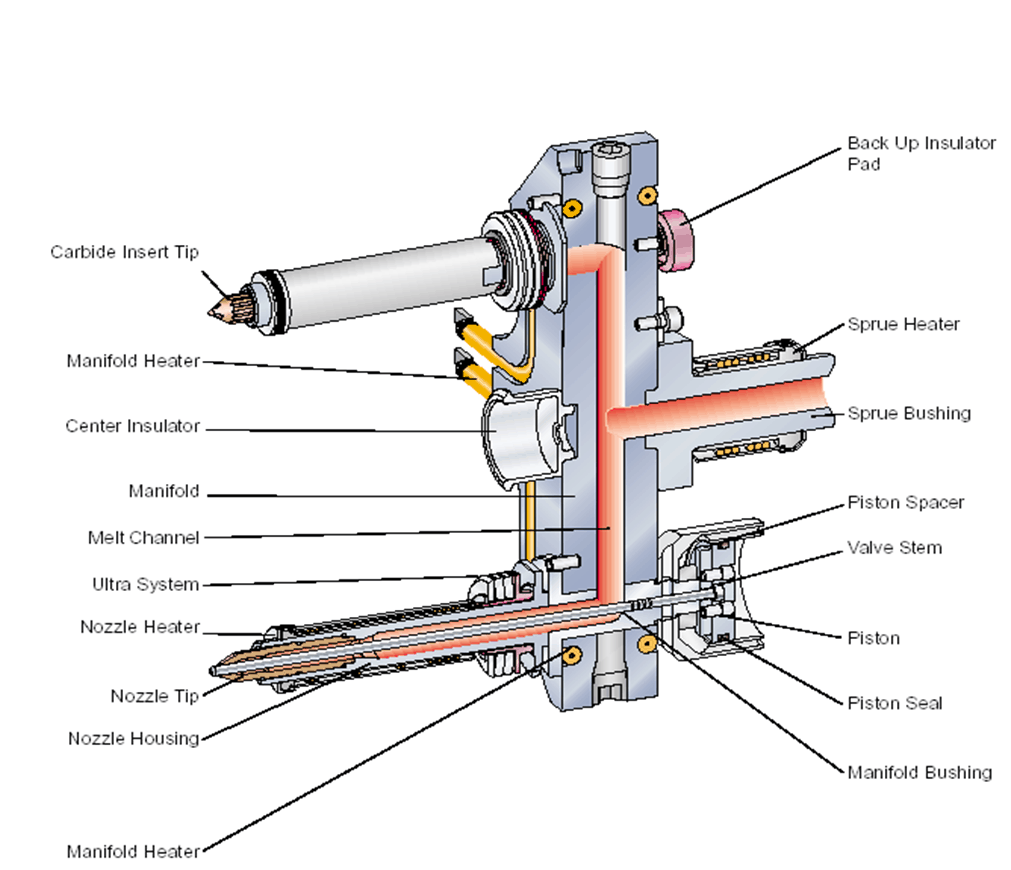

There are three main types of hot runner system:Single hot sprue,Single valve gate and Hot runners with manifold.

Manifold types base on different numbers of gate

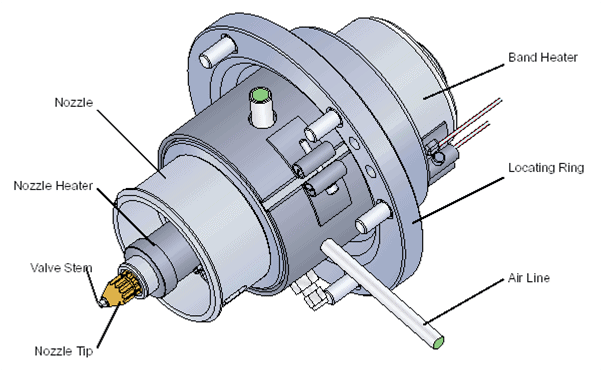

The types of hot nozzle

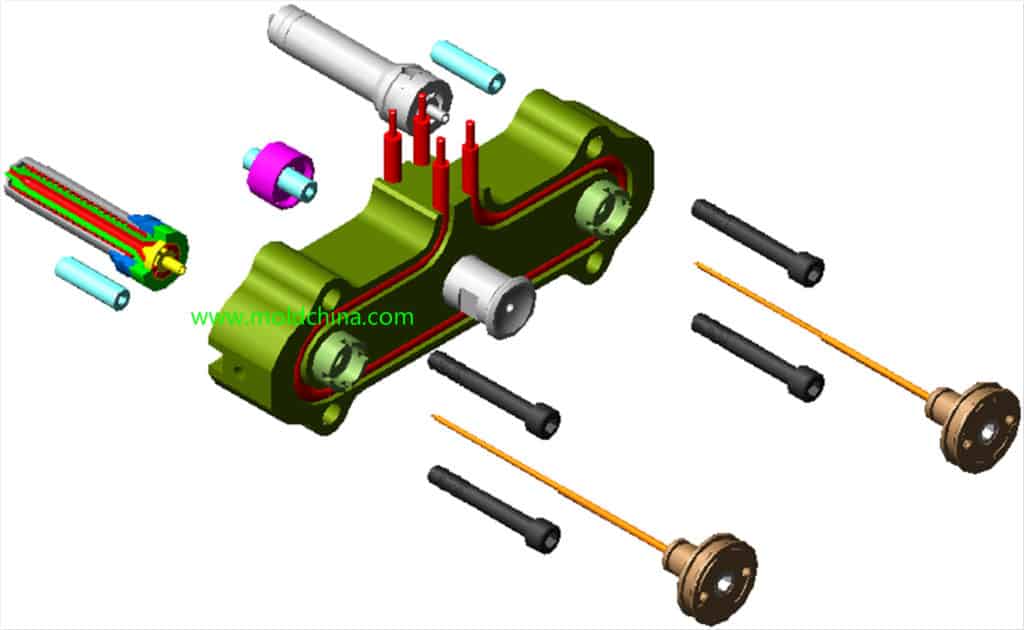

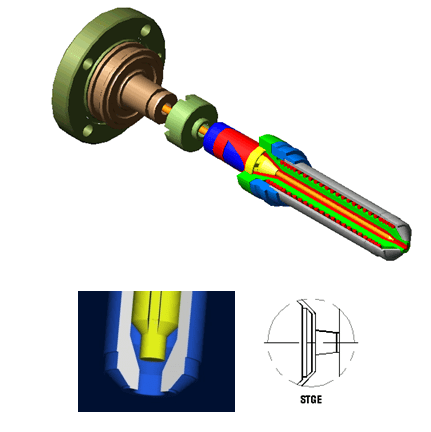

Valve gate

1. Generally suitable for all resins

2. Able to prevent the resin from staying in the gate for too long and causing pollution.

3. Because there is no residual resin, easy for color change

Considerations for Application

1. Precision machining requirements – concentricity and roundness within 5µ

2. Mold core requires to be thermal-treated

3. Guaranteed 1-6 million cycles

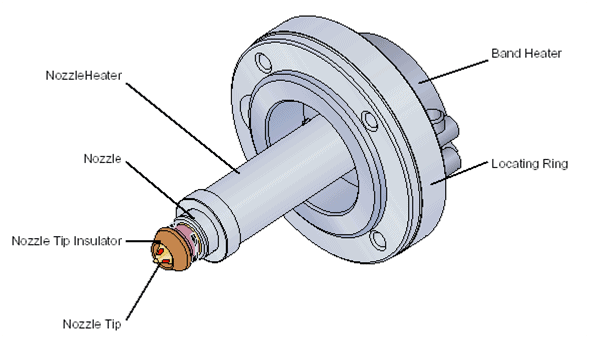

Open Gate(hot tip)

1. Able to replace cold runner pin point gate

2. Nozzle is able to be directly installed on product surface, the gate section is clean

3. Easy to replace needle parts

4.Widely applicable to common resins

Considerations for Application

1. Not suitable for color change

Open gate(big gate)

1.Suitable for semi-hot runner systems

2.Suitable for large products

3.This system is also applicable to glass fiber reinforced resins

Considerations for Application

After the product is formed, there will be a small section of gate on the surface