What is venting system in plastic injection mold?

Venting system, also known as air vents. is a structure that allows the air in the cavity and the gating system to escape in time, and punctually involves air during mold opening and plastic product release, so as to prevent vacuum from forming between the plastic part and the cavity wall.

The purpose of vents: Properly designed venting grooves greatly reduces not only the injection pressure, injection time and pressure holding time, but also the mold clamping pressure, thereby improving the service life and production efficiency of the mold, while lowering the energy consumption of the machine.

The Venting System Design Principles

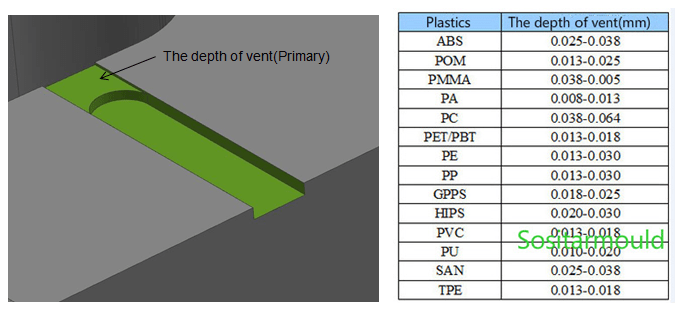

(1)The venting groove can only allow air out, but should keep melt flow in

(2)Design venting grooves of different depths for different plastics, due to their different viscosities;

(3)Venting grooves should be designed in not only the cavity, but also the runner and the cold slug well, so as to minimize air escape from the gating system to mold cavity;

(4)The venting groove has to be extended to the mold base, especially when venting through insert, venting pin or venting insert, you must pay attention to this point;

(5)The venting groove should be machined with a miller, and polished with the 320 sandpaper to remove the knife lines after being machined. Avoid using a grinder to process the venting groove, because the surface processed by the grinder is too flat and smooth, leading to a poor venting effect;

(6)The venting groove on the parting surface should be located on the cavity side, usually on the cavity insert;

(7)A 45° chamfer should be designed on both sides of the venting groove.

Types of Venting System

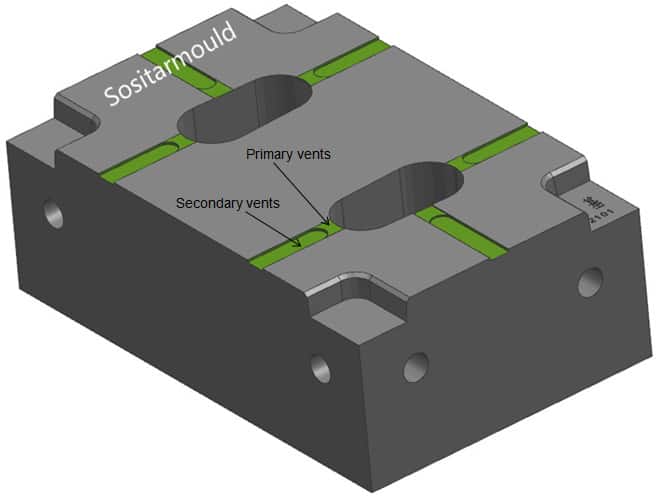

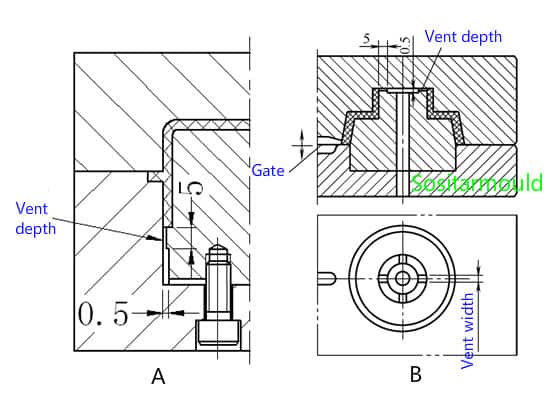

1. Parting-line Vent

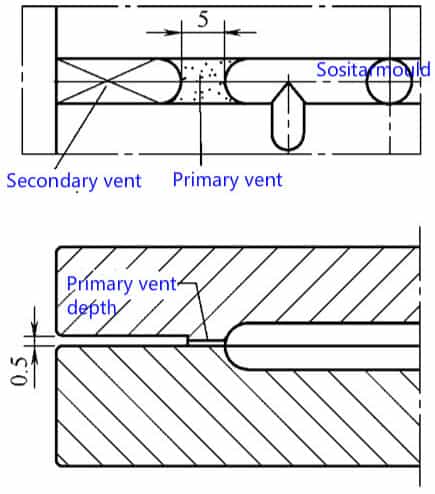

Primary venting groove: The venting groove can only allow air out, but should prevent melt flow leaking. The part close to the cavity is shown as below picture The depth of the primary venting groove is less than the plastic overflow value, and the length is usually about 5mm.Secondary venting groove: In order to vent air smoothly, the groove is deepened to 0.5mm on basis of the primary venting groove. The deepened part is referred to as the secondary venting groove.

2. Gating system vents through the parting line

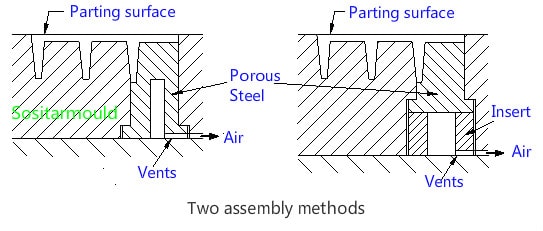

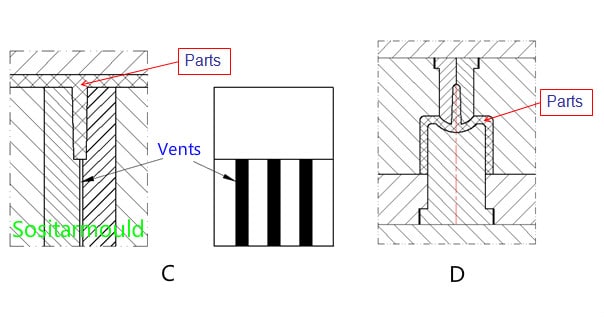

3. Venting through insert mating surface

A.Venting through the clearance on the side of an insert.

B.Venting through the cavity slot or the core kiss-off;

C.Install a grooved slot in the longitudinal location;

D.When it is extremely difficult to vent the cavity, venting inserts can also be designed.

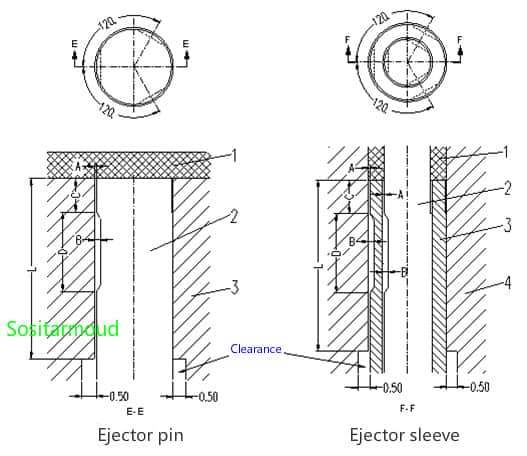

4. Venting through the contact surface between the ejector pin, or the ejector sleeve and the insert

5. Porous Steel

Porous steel is a breathable metal material sintered from metal powder, of which the price is higher than that gold, so it is rarely used in actual design.