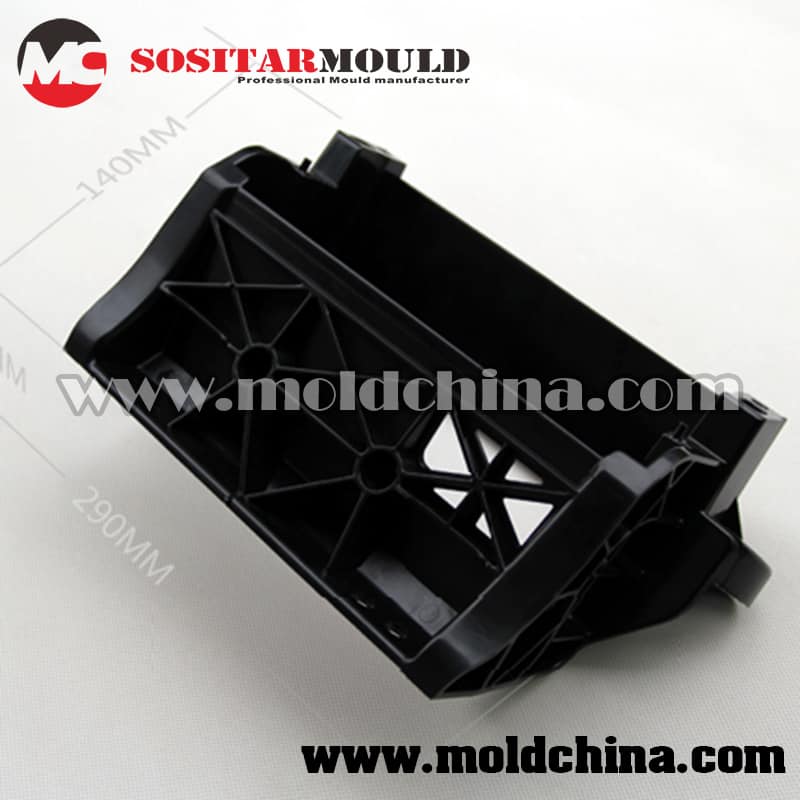

ABS

Acrylonitrile Butadiene Styrene(Abbr.ABS) is synthesized from three chemical monomers – acrylonitrile (C3H3N), butadiene (C4H6) and styrene (C8H8), each of which possesses different characteristics: acrylonitrile is highly strong, and thermally and chemically stable; butadiene features great toughness and impact resistance; styrene is characterized by easy processing, high gloss and strength.

PMMA

Polymethyl methacrylate, abbreviated as PMMA, is an important injection molding thermoplastic that was developed in the earlier stage. The plastic features great transparency, chemical stability and weather resistance.

PP

Polypropylene, Shrinkage Rate: 1.2-1.8%; Relative Density: 0.9-0.91 g/cm3,structrual formula: (C3H6)n .The appearance of PP: White, translucent and waxy when uncolored; natural color, cylindrical and smooth pellets of 2-5mm in any direction; odorless, non-toxic, and no mechanical impurities

POM

Polyoxymethylene or Polyacetal (abbreviated as POM), is a linear polymer compound containing [-CH2-O-] links in the main chain. It is a milky white opaque crystalline linear thermoplastic resin. Its regular molecular structure and crystallinity make it excellent in both physical and mechanical properties, so it is dubbed as the metal plastic.

PC

Polycarbonate (Abbr. PC) is an engineering thermoplastic with an excellent performance, boasting outstanding resistance to impact and creep, as well as great dimensional stability, heat resistance, low water absorption, non-toxicity and excellent dielectric properties. Among the top 5 engineering plastics, it is the only one with great transparency, while also being the fastest growing general engineering plastic in recent years.

PVC

Polyvinyl chloride polymer, or PVC for short, is a thermoplastic resin polymerized by vinyl chloride monomer under the action of an initiator. It is also known as one the five general-purpose resins, while the others are PP, PE, ABS and PS. Molecular Formula: (CH2-CHCl) n.

PA(Nylon)

Nylon (polyamide, abbr.as PA) refers to a injection molding plastic composed of polyamide resins, which can be obtained by polycondensation of diamines and dibasic acids, or by ring-opening polymerization of lactams formed by dehydration of amino acids.There are many types of PA, mainly including PA6, PA66, PA610, PA11, PA12, PA1010, PA612, PA46, PA6T, PA9T and MXD-6 aromatic polyamide, etc.

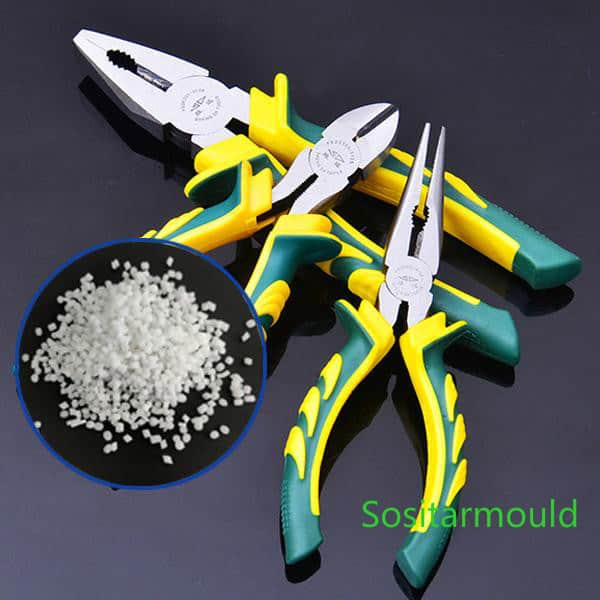

TPE

Thermoplastic Elastomer, AKA TPE,TPE is a material that owns the properties of both the rubber (or the elastomer) and the plastic(i.e., hard segment). The soft segment is elastic, while the hard segment plays a role as a bridging point at normal temperatures to prevent plastic deformation. However, when temperature rises, the plastic components in the hard segment will melt, lose its role as a bridging point, and become plastically deformable, e.g., when molded like a plastic.

HDPE

High density polyethylene (HDPE) is a highly crystalline non-polar thermoplastic resin that features a milky white appearance, with a certain degree of translucency in the thin section. It’s tasteless, odorless and non-toxic natural-colored columnar or oblate pellets with excellent hardness, tensile strength, creep / wear resistance and chemical stability.

PPS

PPS (polyphenylene sulfide) is a white, highly crystalline polymer with a density of 1.34. PPS is a polymer with a thiophenyl group on the main chain of the molecule. Due to its structure that the benzene ring and the sulfur are alternately connected, the molecular chain features a great rigidity and regularity. As a result, PPS is a crystalline polymer with multiple excellent properties, such as heat resistance, rigidity, flame retardancy and electrical insulation.

PET

Polyethylene terephthalate (PET) is also known as polyester. Currently, GF-PET is the most popular variant among the clients.The rheology of the molten state PET is very good, while pressure has a greater influence on its viscosity than temperature. Therefore, the former is mainly leveraged to change the fluidity of PET melt.

PBT

Polybutylene terephthalate, Abbr. PBT, falls into the polyester series. It is a milky white, translucent or opaque crystalline thermoplastic polyester resin polymerized from 1.4-pbt butylene glycol (1.4-butylene glycol) and purified terephthalic acid (PTA) or dimethyl terephthalate (DMT), before going through a mixing process. It is collectively referred to as thermoplastic polyester, or saturated polyester together with PET.