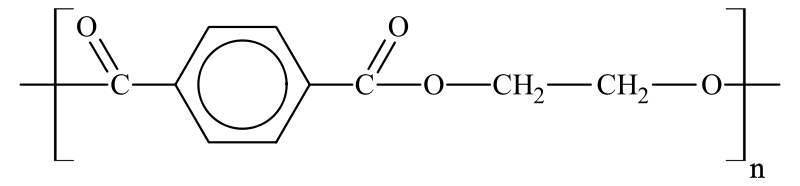

What is PET?

Polyethylene terephthalate (PET) is also known as polyester. Currently, GF-PET is the most popular variant among the clients.The rheology of the molten state PET is very good, while pressure has a greater influence on its viscosity than temperature. Therefore, the former is mainly leveraged to change the fluidity of PET melt.

1. Treatment of the plastic: Since PET macromolecules contain lipid groups, it features a certain degree of hydrophilicity, and its pellets are more sensitive to water at high temperatures. When the water content exceeds the limit, the molecular weight of PET decreases during processing, leading to discolored and brittle final products. As a result, the material must be dried before injection molding, usually for more than 4 hours at 150°C, and 3-4 hours at 170°C. Empty shot can be performed to see whether the material is completely dried. Usually, the proportion of the recycled material that needs to be thoroughly dried, doesn’t exceed 25%.

2. Selection of injection molding machine: PET has a very short stable time after the high melting point. Therefore, an injection system with a multi-stage temperature controller and less self-friction heat generation during plasticization is required. The actual weight of the molded product (including the recycled material) cannot be less than 2/3 of the injection volume of the machine. Based on these requirements, Hwamda has developed the special small and medium-sized PET plasticizing systems in recent years, which are selected when the clamping force is higher than 6300t/m2.

3. Mold and gate design: PET preforms are usually molded by hot runner molds. Therefore, it is the best to design a heat insulator between the mold and the machine plates, of which the thickness should stand at about 12mm to withstand the high pressure. Venting must be sufficient to avoid local overheating or cracking, but the depth of the vent usually does not exceed 0.03mm, otherwise flashing is likely to occur.

4. Melt temperature: Able to be measured via the empty shot method, usually ranging between 270 and 295℃; and 290-315℃ for reinforced GF-PET.

5. Injection speed: Usually, the injection speed should be fast enough to prevent premature solidification during injection molding. But if it is too fast, the high shear rate will make the material brittle. Injection is usually completed within 4 seconds.

6. Backpressure: the lower the better, so as to avoid wear. Usually, the backpressure is no more than 100bar, but unnecessary in most cases.

7. Residence time: Do not keep the residence time too long, so as to prevent the molecular weight from decreasing. Try to avoid temperatures above 300°C. If the shutdown time is less than 15 minutes, only empty shot is needed; if it exceeds 15 minutes, cleaning with viscous PE is required, while lowering the barrel temperature to PE temperature until the machine is turned on again.

8. Considerations: (1). The recycled material should not be too large, otherwise it will be easy to produce the “bridging” effect in the feeding area and thus affect plasticization. ⑵. If the mold temperature or the material temperature is not properly controlled, it is easy to cause “white mist” and non-transparency. If the mold temperature is low and uniform, and the cooling speed is fast, the product will be transparent with little crystallization.

Injection Molding Conditions:

Drying: Drying before injection molding is necessary, because PET is highly hygroscopic. It is recommended to dry the material under 120-165℃ conditions for 4 hours to keep the humidity below 0.02%.

Melting Point: For unreinforced material: 265-280℃; for glass reinforced material: 275-290℃.

Mold Temperature: 80-120℃。

Injection Pressure: 300-1300bar。

Injection Speed: A higher injection speed can be adopted on condition that embrittlement is not caused.

Runner & Gate: All conventional types of gates can be used, and the gate size should be 50-100% of the thickness of the plastic part.

Chemical & Physical Properties: The glass transition temperature of PET is around 165℃, while its crystallization temperature ranges between 120 and 220℃. PET is very hygroscopic at high temperatures. For glass fiber reinforced PET materials, bending deformation also very easily occurs at high temperatures. The degree of crystallization of the material can be increased by adding crystallization enhancers.transparent products made of PET have gloss and heat distortion temperature. Special additives such as mica can be added to PET to minimize its bending deformation. If a lower mold temperature is adopted, transparent products can also be obtained by using unreinforced PET materials.