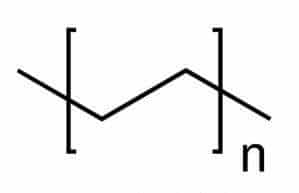

High density polyethylene (HDPE) is a highly crystalline non-polar thermoplastic resin that features a milky white appearance, with a certain degree of translucency in the thin section. It’s tasteless, odorless and non-toxic natural-colored columnar or oblate pellets with excellent hardness, tensile strength, creep / wear resistance and chemical stability.

Physical & Chemical Properties

The high crystallinity of HDPE leads to its high density, high tensile strength, high distortion temperature, high viscosity and high chemical stability.

Compared with PE-LD, HDPE is more resistant to penetration with a low impact strength. The characteristics of PE-HD are mainly determined by its density and molecular weight distribution. HDPE, which is suitable for injection molding, has a very narrow molecular weight distribution, leading to its good fluidity, with an MFR between 0.1 and 28. The higher the molecular weight, the worse the fluidity of LDPE, but the better the impact strength.

LDPE is a semi-crystalline material with a high post-molding shrinkage between 1.5% and 4%.

HDPE is prone to environmental stress cracking, but the internal stress can be reduced by using materials with very low fluidity, thereby minimizing cracking. HDPE is easy to dissolve in hydrocarbon solvents when the temperature is above 60°C, but its resistance to solubility is higher than that of LDPE.

Injection Molding Process

Drying: Unnecessary if properly stored

Melting temperature: 220-260°C. For materials with larger

molecules, the recommended melting temperature range is between 200 and 250°C.

Mold temperature: 50-95°C. Plastic parts with wall thickness below 6mm should adopt a higher mold temperature, and those with wall thickness above 6mm should adopt a lower mold temperature. The cooling temperature of the plastic parts should be as uniform as possible, so as to reduce the difference in shrinkage. For the optimal molding cycle, the diameter of the cooling channel should not be less than 8mm, and its distance to the mold surface should be kept within 1.3d (“d” stands for the diameter of the cooling channel).

Injection Pressure: 700-1050bar.

Injection Speed: High speed injection is recommended.

Runner & Gate: The diameter of the runner is between 4 and 7.5mm, and the length should be as short as possible. Various types of gates can be used, but the gate length should not exceed 0.75mm. It’s especially suitable for hot runner molds.

Combined with Color Additives

The addition of antioxidants is able to prevent polymer degradation during molding and product oxidation during application. Antistatic additives are applied to many packaging-grade products, in a bid to reduce dust and dirt from adhering to bottles or packages. Specific applications require special additives, such as copper inhibitors related to wire and cable applications. Excellent resistance to weather and ultraviolet (or sunlight) can be obtained by adding anti-UV additives. PE without addition of anti-UV additives or carbon black is not recommended for continuous outdoor applications. High-grade carbon black pigment offers excellent UV resistance, so suitable for outdoor applications, such as wires, cables, tank liners or pipes.

Application Scope

Typical Applications:

Refrigerator containers, storage containers, household kitchenware, airtight

lids, etc.