A Brief Introduction to Injection Molding of PVC

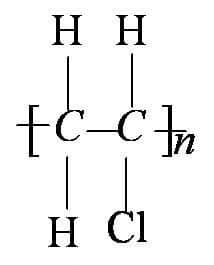

Definition: Polyvinyl chloride polymer, or PVC for short, is a thermoplastic resin polymerized by vinyl chloride monomer under the action of an initiator. It is also known as one the five general-purpose resins, while the others are PP, PE, ABS and PS. Molecular Formula: (CH2-CHCl) n.

Thanks to its low price, inherent anti-inflammatory performance, outstanding toughness, strength and chemical resistance, as well as low shrinkage rate of 0.2-0.6%, the PVC material is increasingly applied in electrical appliances, machinery, construction, daily necessities, toys, and packaging industries. According to the characteristics of PVC, the injection molding process is analyzed as follows:

I. Features of PVC

The thermal stability of PVC is poor, its molding temperature is close to the decomposition temperature; and the fluidity is not good, so appearance defects are easy to occur. With a poor heat resistance, the PVC material is most easily scorched, generating acid gases that erode the mold. During the plastic injection molding process, plasticizer can be added to increase its fluidity. It is usually applied with additives to increase its strength, electrical insulation and chemical resistance.

II. Mold & Gate Design

In order to reduce the injection molding cycle, the shorter the nozzle, the better; the cross section should be round; the cone-shaped nozzle (with an internal angle of 5 degrees) should have a diameter of at least 6mm. A cold slug well is preferred, because it is able to prevent the poorly melted semi-solid materials that may affect the surface finish and product strength from entering the mold cavity.

The draft angle should be designed between 0.50 and 10 degrees to ensure that

there are sufficient vents in the mold cavity. The commonly used vent holes are

0.03-0.05mm deep and 6mm wide, or the clearance around each ejector pin is

0.03-0.05mm. The mold should be made of stainless steel or hard chrome plated.

III. PVC Injection Molding Process

PVC is a heat-sensitive plastic. Excessive heat or excessive shearing will cause decomposition that spreads quickly, because one of the decomposition products (such as acid or HCI) produces a catalytic effect, causing the material to further decompose and generate acidic substances that erode metal, which not only causes depression, but also peels off the protective layer of the metal, leading to rust, thus more harmful to the human body.

The commonly adopted screw length-diameter ratio is 18-24:1, the ratio of the three

sections is 3:5:2, and the compression ratio is 1.8-2. The recommended screw thread

depth of the feed section is as follows:

Screw Diameter (mm): 35 50 60 75 100

Screw Thread Depth (mm): 2 3 4 5 6

The tip of the screw should have an internal angle of 25 to 30 degrees. When

the screw is injected in place, the distance between the tip and the nozzle

should be 0.7 to 1.8mm. The screw must be made of stainless steel or chrome

plated.

1). Screw Padding: The screw padding is between 2 and 3mm, and larger for large-sized

machines.

2). Injection Volume: The actual barrel residence time cannot exceed 3 minutes.

3). Barrel Temperature Setting:

The temperature provided is for reference only. Appropriate adjustments can be

made according to the actual situation of the machine and raw material, which

may exceed the recommended range.

Location: Mold / Nozzle / Front Section / Mid Section / Feed Section

Temperature (°C): 30-60 / 170-190 / 160-180 / 150-170 / 140-160

The injection volume applied is 20-85% of the theoretical injection volume of the injection molding machine. The lower the actual injection volume, the longer the residence time of the material, and the greater the risk of degradation after being heated.

4). Barrel Residence Time

Under 2,000 °C temperature conditions, the barrel residence time (of the plastic material) can be more than 5 minutes.

5). Injection Speed

The injection speed should be slow, otherwise excessive shearing will degrade the material. When UPVC is used to produce extremely smooth thick-walled products, multi-stage injection speed should be applied. If light brown stripes leak out from the gate, the injection speed would be too fast.

6) Back pressure

The commonly used surface value is 5 bar. Though increasing the back pressure is helpful for color mixing and venting, the back pressure should be kept as low as possible.

7) Shutdown

Due to the low thermal stability of PVC, the shutdown part is very important. The barrel should be cleaned by using other thermoplastics with high thermal stability and non-resistance to PVC (such as PMMA, PP, LDPE, or GPPS). Don’t mix POMT and UPVC in the same barrel, or it will lead to excessive chemical reaction and cause serious damage to the machine.

8) Mixing ratio

The maximum mixing ratio of degraded material is 20%, or product quality will be affected.

9) Typical products

The main application of UPVC is to produce drainage pipes, or computer / television casing, water filter groove, photocopying machine casing, electric and gas meter casing, transparent cover of printer, air grating and various electronic parts.