In the design of plastic products, bosses and screw holes are two indispensable products for final assembly. The following are some technical information about the assembling bosses and holes of plastic products.

1.About bosses

a. When designing a boss, consider whether the location will shrink;

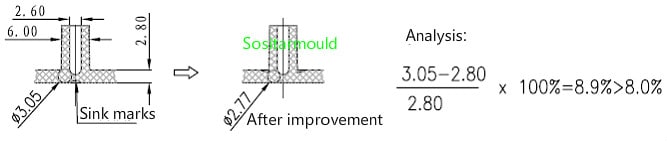

b. In order to improve the strength of bosses, ribs can be added around it. Refer to Fig. 1 for the width of the rib.

Refer to Fig. 1 and Fig. 2 to see how we can improve the shrinkage of a stud: The wall of the boss is too thick before improvement, so it is prone to shrinkage; and after improvement, it will not shrink.

2. About screw holes

a. The distance between holes is usually more than 2 times the hole diameter.

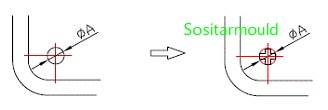

b. The distance between the hole and the edge of a plastic productis usually more than 3 times the hole diameter. If it is limited by the design of the plastic product, or used as a fixing hole, the edge of the hole can be reinforced by using a boss.

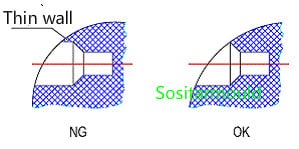

c. When designing a side hole, we should avoid thin-walled sections, otherwise sharp corners will be produced, which may cause injury to hands or easy material shortage.

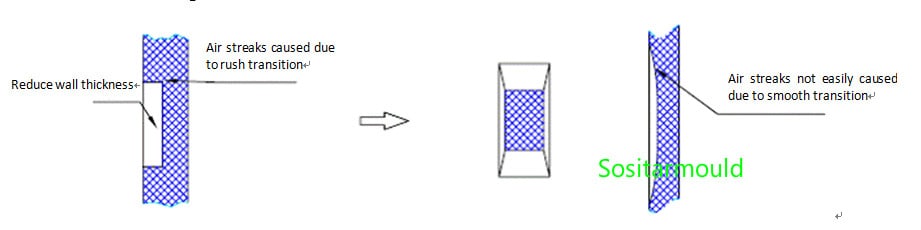

3. About “reducing wall thickness”

2. Boss design

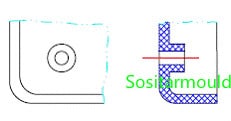

2.1. Usually, two shells are fixed together by a boss and a buckle, and the former also plays an important role in securing the PCB board.

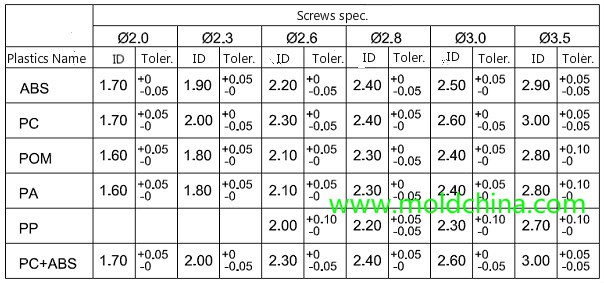

2.2. The principle of bosses design for self-tapping screws is: its outer diameter should be 2.0 to 2.4times the outer diameter of the screw. In real-world design: boss outer diameter = 2×screw outer diameter; boss inner diameter (ABS, ABS+PC) = screw outer diameter -0.40mm; boss inner diameter (PC) = screw outer diameter -0.30-0.35mm (during design, we can start with 0.30mm, and then modify the mold to increase its wall thickness after test fails); the distance between the two shell bosses is 0.05mm.

2.3. The torque values required for the assembly and testing of common self-tapping screws (10 times) are shown in Table 3.