How the slide work in plastic injection mold?

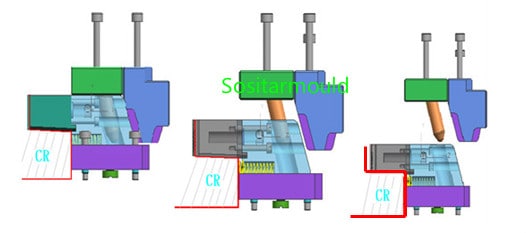

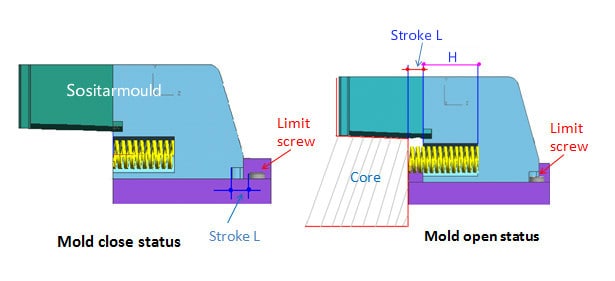

In a plastic injection mold, the mold opening action is leveraged to create a relative movement trend between the angle pin and the slide, so that the slide moves in two directions – the mold opening direction and the horizontal direction – to release it from the undercut. See the diagrams below:

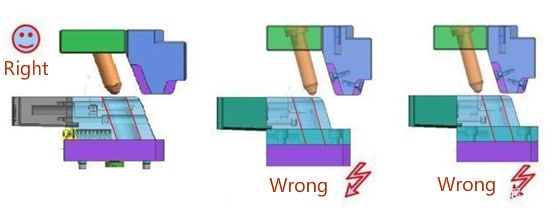

The slide has to move a certain distance during the mold opening process. After the mold core and cavity are completely separated, the slide should be able to return safely. Also, the slide should stop at the correct location. If it continues sliding forward or backward, the angle pin will collide with the hole due to misalignment when the mold closes! Therefore, a flexible and reliable positioning device must be installed on the slide, to ensure that the slide stays in place.

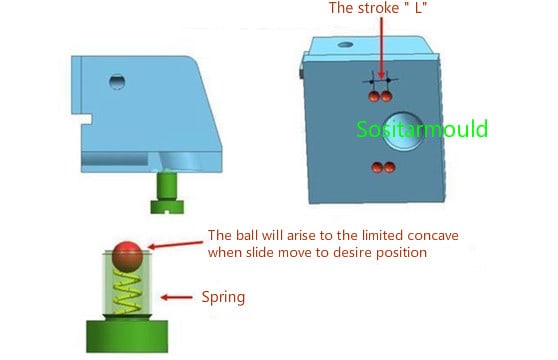

1. Spring ball: The advantages include easy processing and simple operation; while the disadvantage is that it is easy to damage; commonly used for small slides in the X direction (horizontal), as well as slides with a long stroke. It is also able to help delay the opening of the slide, because the ball will resist the slide when the angle pin is not engaged.

2. Spring and Limit Screw

The advantages include convenient processing and safe positioning; commonly used for slides in the X & Y directions, as well as those with a short stroke. Spring calculation: first of all, you need to know that the preload of the slide spring needs to ensure that preload still exists when the mold is opened and the undercut is released. Its purpose is to overcome the gravity of the slide and stop it from returning by the elastic force generated by the preload.

(L stroke + 3-5 preload) / 40% = L0 (free length)

Spring hole depth: H = L0 – preload – stroke

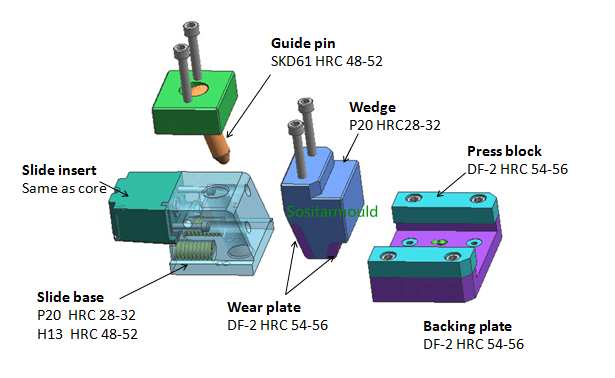

The steel material for slide components

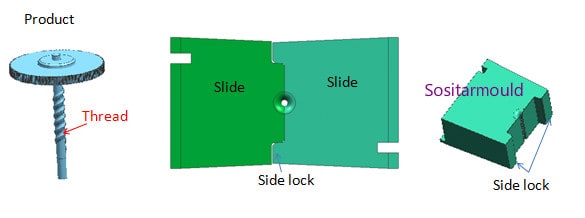

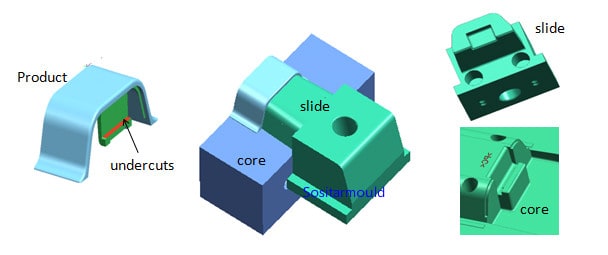

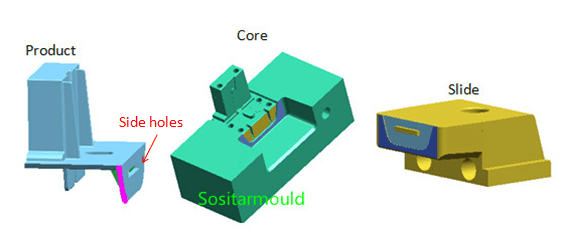

Some cases for slide application

1)Slide for undercuts release

2)Slide for side holes

3)Slide for thread