Gisbert Ledvon

If you build a multi-cavity with a large surface area in each cavity, consistency in surface finish and surface integrity is a must. Otherwise, you will get surface finish differences on the molded parts and may have difficulties ejecting the parts from the cavity.

However, large surfaces that are EDM’ed via diesinking often appear to show different surface finishes. You may believe that a faster pulsation will flush out the particles faster and yield a consistent spark all the way around your electrode. This will indeed work for ribs or small cavity applications, but if you have a large electrode – e.g., ski goggles (see Figure 1) – the hydraulic suction during pulsation will lift the workpiece off the table or the electrode off of the electrode holder.

Figure 1: A combination of technological components must work together in order to ensure a uniform surface finish.

Key Components

A combination of technological components must work together in order to control the EDM process and to ensure a uniform surface finish. These key components have been incorporated into some new diesinking machines. These features include:

Elimination of Short Circuits

During machining, short circuits may occur due to particles that are trapped between the electrode and the workpiece. New diesinking machines feature tools that eliminate these short circuits. This is accomplished by applying a powerful discharge, which lasts only a fraction of a second. Particles are broken into smaller pieces so they can be flushed out during normal pulsation.

Spark Monitoring

This new system constantly monitors what happens in the spark gap at microsecond intervals and responds instantly to any degenerating spark conditions that may occur. To deliver perfect surface finishes, the system checks each spark during finishing.

Servo Control System

A new system found in some diesinking machines uses a dielectric-cooled AC motor connected to the ball screw, which ensures maximum accuracy. Utilizing proven ball screw technology, the operator has the option of cutting either with large or small electrodes – unattended – at any time. No manual adjustments are needed to compensate for different electrode weights such as linear motors. Fast acceleration speed – up to four times faster than on previous models – is not compromised by the servo control system, and it can decrease cutting times of deep ribs (3.9 inches deep) by as much as 87 percent.

But there is more beyond this small application segment, so let’s get back to the real world of applications that moldmakers have to deal with every day.

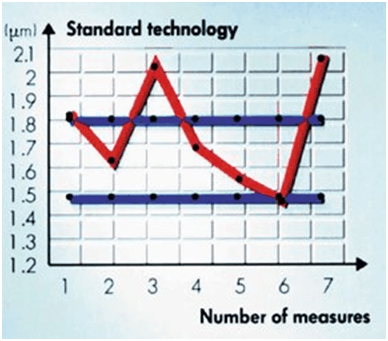

Figure 2: Surface finish in a large cavity.

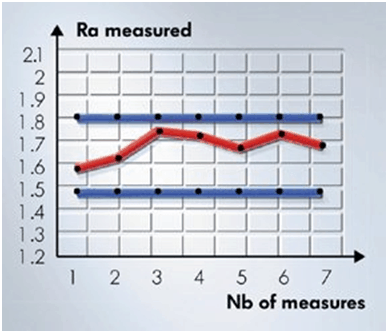

In Figure 2, you can see the results measuring the surface finish in seven different areas of the large cavity. The deviation was 12.2 percent. A combination of the new spark monitoring system, the new servo control system and “surface technology” yielded an even surface finish throughout the seven points measured in the cavity (see Figure 3). Moreover, the surface finish deviation was only 3.4 percent (see Figure 4).

Figure 3: All seven points featured an even finish.

Cutting Carbide

Cutting carbide with diesinking machines was always possible, but was limited to high wear. This caused inaccuracy of geometrical details and surface finish results not better than 0.4 mm or 16 minch RA. It also led to very long cutting times.

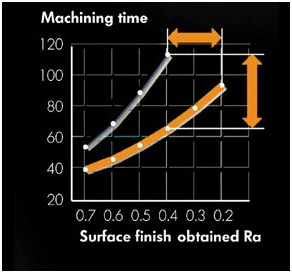

The new spark technology for cutting carbide and the new servo system helps to reduce cutting time and electrode wear, and also affords a better surface finish by cutting carbide. Standard servo systems are not able to act fast enough to avoid closing the gap between electrode and part – causing contamination and high wear when cutting carbide because of the small spark gaps. The results are simply spectacular. Surface finish is improved to 0.2 mm or 8.0 minch RA. Timesavings also are improved 25 percent to 40 percent when compared with previous models (see Figure 4).

Figure 4: Surface finish deviation.

Finally, it does not matter how fast you can move in and out of the cavity during pulsation. If you cut medium to large cavities – and this is what 80 percent of moldmakers do – the technology and control of the spark to perfection will give you unsurpassed performance.